Chitosan everything you need to know – Chitosan: everything you need to know dives deep into this fascinating biopolymer. From its origins in chitin to its diverse applications, we’ll explore the science behind chitosan and its impact across industries. This comprehensive guide covers everything from its chemical structure and extraction methods to its remarkable properties and potential future applications.

This detailed look at chitosan will explore its unique properties, including biocompatibility, biodegradability, and antimicrobial activity. We’ll examine its use in food packaging, wound healing, water treatment, and more. Understanding chitosan’s manufacturing process, safety, and regulatory aspects is crucial to appreciating its full potential. This discussion will be insightful and informative.

Introduction to Chitosan

Chitosan is a natural polysaccharide derived from chitin, a ubiquitous biopolymer found in the exoskeletons of crustaceans and the cell walls of fungi. Its unique properties, stemming from its chemical structure, have led to a wide range of applications in various industries, from food packaging to wound healing. This exploration delves into the fundamental aspects of chitosan, including its chemical makeup, extraction processes, and diverse grades.

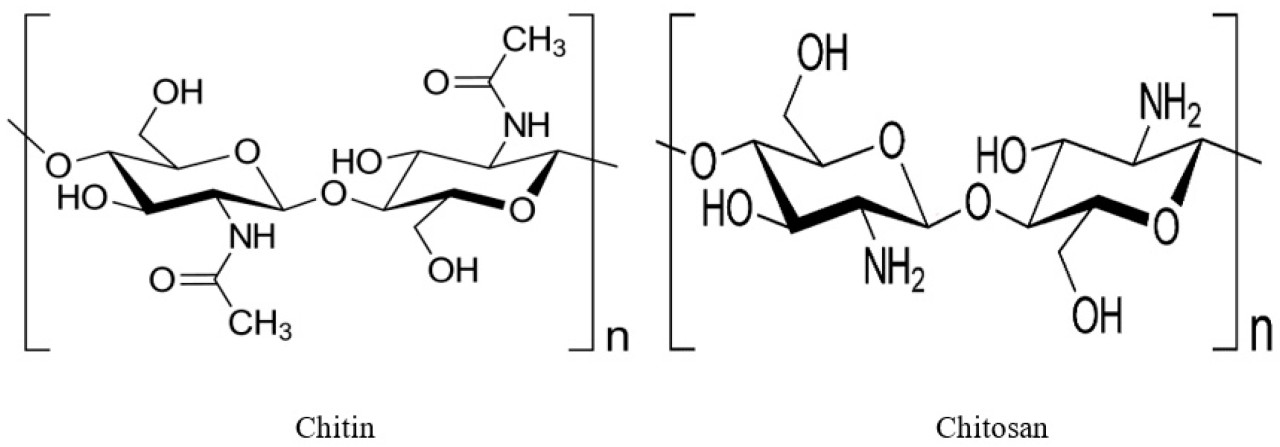

Chemical Structure and Relation to Chitin

Chitosan is a linear polysaccharide composed of randomly distributed N-acetyl-D-glucosamine and D-glucosamine units. The difference between chitosan and chitin lies in the degree of deacetylation. Chitin, the precursor, has a higher proportion of N-acetyl-D-glucosamine units. Chitosan, on the other hand, is formed by the deacetylation of chitin, resulting in a polymer with amine groups (-NH 2) along its backbone.

This crucial difference in structure bestows upon chitosan unique properties compared to chitin.

Chitosan’s amino groups give it positive charges under acidic conditions, making it soluble in dilute acids like acetic acid.

Chitosan Extraction from Chitin Sources

The process of chitosan extraction involves several steps, starting with the preparation of the chitin source. The chitin is typically obtained from crustacean shells or fungal cell walls. These sources are then treated with alkali solutions to remove impurities. The crucial step involves deacetylation, where the N-acetyl groups on the chitin are removed using alkaline solutions, typically containing sodium hydroxide (NaOH) or ammonium hydroxide (NH 4OH).

The final product is chitosan, a polymer with varying degrees of deacetylation, depending on the process parameters. The purity and quality of the final chitosan are influenced by the effectiveness of the deacetylation process and subsequent purification steps.

Types of Chitosan Based on Deacetylation

The degree of deacetylation (DD) is a critical factor in determining the properties of chitosan. Different DD values result in different types of chitosan, each exhibiting unique characteristics. The degree of deacetylation is expressed as a percentage. A higher DD value signifies a greater proportion of deacetylated units. These differences in structure influence the physical and chemical behavior of chitosan.

Comparison of Chitosan Grades

| Chitosan Grade | Degree of Deacetylation (%) | Solubility | Viscosity | Mechanical Strength | Applications |

|---|---|---|---|---|---|

| Low DD | 20-40 | Poor in acidic solutions | Low | Low | Animal feed, agriculture |

| Medium DD | 40-60 | Moderate in acidic solutions | Moderate | Moderate | Food packaging, wound dressings |

| High DD | 60-95 | Good in acidic solutions | High | High | Biomedical implants, drug delivery |

The table above summarizes the general properties of different chitosan grades. These properties are influenced by the degree of deacetylation and can be tailored for specific applications by controlling the extraction and purification process. For instance, high DD chitosan, with its good solubility and high viscosity, is suitable for biomedical applications like tissue engineering, while low DD chitosan finds use in agricultural applications.

Properties and Characteristics

Chitosan, a natural polymer derived from chitin, boasts a unique array of properties that make it a versatile material in various applications. Its biocompatibility, biodegradability, and antimicrobial action are particularly noteworthy, leading to its exploration in biomedical and environmental sectors. Understanding these properties, along with its physical and chemical characteristics, is crucial to harnessing its full potential.Chitosan’s remarkable features stem from its chemical structure and unique interactions with its environment.

Its ability to form films, gels, and fibers, coupled with its responsiveness to different stimuli, allows for tailoring its properties to specific needs. Comparing chitosan with other biopolymers highlights its advantages, while examining processing methods reveals the intricate relationship between these methods and chitosan’s final characteristics.

Biocompatibility and Biodegradability

Chitosan is generally recognized as biocompatible, meaning it is well-tolerated by living tissues. This property is a significant advantage in biomedical applications, where the material’s interaction with the body is critical. Its biodegradability further enhances its suitability for temporary implants or drug delivery systems. The body can break down chitosan into non-toxic substances, reducing the risk of long-term complications.

Antimicrobial Activity

Chitosan possesses inherent antimicrobial properties, exhibiting activity against a range of bacteria, fungi, and viruses. This property stems from its positive charge, which can disrupt the cell walls of microorganisms. The antimicrobial effect of chitosan has shown promising results in food preservation and wound healing applications.

Physical and Chemical Characteristics

Chitosan’s physical and chemical characteristics significantly influence its applications. Solubility in acidic solutions is a key property, affecting its processing and applications. Viscosity, determined by molecular weight and degree of deacetylation, is another critical factor, influencing the texture and handling of chitosan-based products. Molecular weight directly affects the size and shape of chitosan molecules, impacting its performance in different applications.

Comparison with Other Biopolymers

Compared to other biopolymers like cellulose or alginate, chitosan exhibits unique properties. Its positive charge and solubility in acidic solutions distinguish it, enabling specific interactions with its environment. While cellulose is a structural component, chitosan’s biodegradability and antimicrobial properties provide advantages in biomedical and other applications. Alginate, while biocompatible, does not possess the same antimicrobial capabilities as chitosan.

Impact of Processing Methods

Processing methods significantly affect chitosan’s final properties. Solvent casting, for example, can influence the film’s thickness and mechanical strength. Extrusion, on the other hand, is suitable for creating fibers with specific shapes and textures. Different processing techniques can lead to varying degrees of crystallinity and porosity, impacting the material’s overall performance.

Applications Table

| Property | Application | Mechanism |

|---|---|---|

| Biocompatibility | Biomedical implants | Facilitates tissue integration and reduces inflammation |

| Biodegradability | Drug delivery systems | Controlled release of active compounds |

| Antimicrobial activity | Food packaging | Preserves food quality by inhibiting microbial growth |

| Solubility | Coatings and films | Enables uniform dispersion and adhesion |

| Viscosity | Gels and pastes | Provides desired texture and consistency |

| Molecular weight | Wound dressings | Affects mechanical strength and drug delivery |

Applications of Chitosan

Chitosan, a biopolymer derived from chitin, exhibits a remarkable array of applications across diverse industries. Its unique properties, including biocompatibility, biodegradability, and antimicrobial activity, make it a valuable material in various fields. This versatility stems from its ability to interact with different substances and environments, offering a sustainable alternative to traditional materials.Chitosan’s widespread use is driven by its natural origin, safety profile, and potential for diverse applications.

Its ability to modify existing materials or act as a stand-alone substance positions it for use in various sectors.

So, you’re diving into chitosan, huh? It’s a fascinating natural polymer, and there’s a lot to unpack about its uses. While exploring the many benefits of chitosan, it’s worth noting that some of the same principles behind its effectiveness can be seen in other natural substances. For instance, the potent health benefits of shilajit, a naturally occurring mineral substance, the benefits of shilajit are often linked to its unique composition.

Ultimately, understanding chitosan requires looking at the broader picture of natural compounds and their potential impacts. That’s why knowing about chitosan, and the related compounds, is so important.

Food Packaging

Chitosan’s film-forming ability makes it an attractive alternative to synthetic plastics in food packaging. Its biodegradability and barrier properties enhance food safety and extend shelf life. Chitosan films can be tailored to specific food types, offering tailored protection against moisture, oxygen, and microorganisms. This contributes to reduced food waste and environmental impact.

Wound Healing and Tissue Engineering

Chitosan’s biocompatibility and biodegradability make it a promising material for wound healing and tissue engineering applications. Its ability to promote cell growth and tissue regeneration makes it a valuable component in wound dressings and scaffolds. These applications leverage chitosan’s ability to create a supportive environment for cells to proliferate and repair damaged tissues.

Water Treatment and Purification

Chitosan’s unique properties allow it to effectively remove pollutants from water. Its ability to adsorb heavy metals, pesticides, and other contaminants makes it a valuable tool in water purification. This application leverages chitosan’s high surface area and ability to bind to various substances.

Agriculture and Aquaculture

Chitosan’s antimicrobial properties make it a valuable tool in agriculture and aquaculture. Its ability to control plant diseases and fish pathogens has significant implications for both crop production and fish farming. This application leverages chitosan’s natural antimicrobial action to protect plants and animals from harmful microorganisms.

Cosmetics and Personal Care Products

Chitosan’s unique properties have led to its incorporation into cosmetics and personal care products. Its ability to enhance skin hydration, promote cell regeneration, and act as a humectant makes it a valuable ingredient. This application leverages chitosan’s biocompatibility and interaction with the skin.

Summary Table of Chitosan Applications

| Industry | Application | Advantages | Disadvantages |

|---|---|---|---|

| Food Packaging | Food packaging films | Biodegradable, barrier properties, extends shelf life, reduces food waste | Cost, film strength, barrier properties may vary depending on food type |

| Wound Healing/Tissue Engineering | Wound dressings, scaffolds | Biocompatible, biodegradable, promotes cell growth, tissue regeneration | Scalability, cost, potential for immune response |

| Water Treatment | Removal of pollutants | Effective adsorbent for heavy metals, pesticides, etc., environmentally friendly | Efficiency may vary depending on the contaminant, potential for clogging |

| Agriculture | Controlling plant diseases | Natural antimicrobial agent, enhances crop production | Effectiveness may vary depending on the disease, potential for environmental impact |

| Aquaculture | Controlling fish pathogens | Natural antimicrobial agent, enhances fish health, reduces disease outbreaks | Effectiveness may vary depending on the pathogen, potential for environmental impact |

| Cosmetics | Skin care products | Skin hydration, cell regeneration, humectant | Skin sensitivity, efficacy varies |

Production and Manufacturing

Chitosan, a biopolymer with diverse applications, is derived from chitin, a natural polymer found in the exoskeletons of crustaceans and the cell walls of fungi. Understanding the methods used to produce chitosan is crucial for ensuring its quality and cost-effectiveness. Different production methods yield chitosan with varying properties, influencing its final application.The production process, from raw material selection to final product quality control, requires meticulous attention to detail.

This section delves into the intricacies of chitosan manufacturing, exploring the different approaches, raw materials, and crucial quality control steps.

Raw Materials for Chitosan Production

The primary raw material for chitosan production is chitin, obtained from various sources. Crustacean shells are the most common source, followed by fungal cell walls. The quality and purity of the chitin directly impact the resulting chitosan. Factors like the source, processing conditions, and contaminants in the raw chitin all affect the final product.

Methods for Chitosan Production

Several methods exist for converting chitin into chitosan. These methods differ in their chemical processes and consequently affect the chitosan’s properties.

- Acid Hydrolysis: This method involves treating chitin with a strong acid, typically sulfuric acid or hydrochloric acid, to deacetylate the chitin. The process converts chitin into chitosan by removing acetyl groups. The reaction conditions, including acid concentration, temperature, and reaction time, significantly influence the degree of deacetylation and the resulting chitosan’s properties. For example, a higher acid concentration might increase the rate of deacetylation but could also lead to the degradation of chitosan molecules.

- Enzymatic Hydrolysis: Enzymes, such as chitinases, can also be employed to deacetylate chitin. This method often yields chitosan with a more controlled degree of deacetylation, compared to acid hydrolysis. The enzymatic method, though potentially more expensive, is environmentally friendly as it avoids the use of strong acids. Furthermore, the reaction conditions are easier to control and lead to a higher degree of deacetylation.

Diving into chitosan, it’s fascinating how this natural polymer is used in everything from skincare to wound healing. But did you know that vitamin D, specifically the differences between vitamin D2 and vitamin D3 vitamin d two vs d three , can impact its effectiveness? Understanding these nuances is key to getting the most out of chitosan’s potential benefits, so keep exploring the world of chitosan with me!

Step-by-Step Procedure for Chitosan Production

A typical acid hydrolysis process involves these steps:

- Raw Material Preparation: Chitin sources, such as crustacean shells, are cleaned, crushed, and often bleached to remove impurities. This step ensures a high-quality starting material.

- Acid Treatment: The prepared chitin is treated with a strong acid, like sulfuric acid, under controlled temperature and time. The specific conditions are crucial for achieving the desired degree of deacetylation.

- Neutralization: The acidic solution is neutralized to stop the reaction and precipitate the chitosan. Carefully selecting the neutralizing agent (e.g., sodium hydroxide) is essential to prevent further degradation.

- Washing and Drying: The chitosan is washed extensively to remove residual acid and impurities. Drying is crucial to maintain the chitosan’s structural integrity and prevent microbial growth.

- Purification: Further purification steps, such as filtration and centrifugation, might be necessary to remove any remaining impurities and ensure a high-purity product.

Comparison of Production Methods

| Method | Efficiency | Cost-Effectiveness | Environmental Impact |

|---|---|---|---|

| Acid Hydrolysis | Generally higher | Potentially lower due to lower reagent costs | Higher due to acid usage |

| Enzymatic Hydrolysis | Lower, but more controlled | Higher due to enzyme costs | Lower due to no strong acids |

The table highlights the trade-offs between different production methods. The choice of method often depends on the desired properties of the final chitosan product and the budget constraints of the manufacturer.

Quality Control in Chitosan Production, Chitosan everything you need to know

Maintaining consistent quality throughout the chitosan production process is paramount. Testing for the degree of deacetylation, molecular weight, and the presence of contaminants is crucial. This ensures the product meets the required specifications for various applications. Consistent quality control measures minimize variations in the product’s properties, which can significantly affect its effectiveness in applications.

Flowchart of Chitosan Production

A flowchart would visually represent the entire process, from raw material preparation to the final chitosan product. It would display each step, including raw material input, treatment, separation, purification, and the final product output. This visual representation would illustrate the interconnectedness of each stage in the process.

Safety and Regulations

Chitosan, derived from chitin, has a long history of safe use in various applications. However, as with any material, understanding its safety profile and regulatory framework is crucial for responsible use. This section delves into the safety and toxicity of chitosan, outlining regulatory aspects and potential health benefits and risks. It also details the regulations governing chitosan in different countries and presents a summary table for quick reference.Chitosan’s safety is generally considered good, particularly in food applications.

Its biodegradability and biocompatibility contribute to its low toxicity profile. However, specific applications and dosage levels may vary in their impact. Understanding the regulations and safety guidelines ensures responsible use across industries.

Chitosan Safety and Toxicity

Chitosan’s biocompatibility, stemming from its natural origin and inherent properties, often results in low toxicity. However, the degree of toxicity can depend on factors such as the source material, processing methods, and the intended application. Research indicates that orally administered chitosan is generally safe for consumption in recommended dosages. Potential allergic reactions are possible, though uncommon.

Diving into chitosan everything you need to know reveals a fascinating substance with potential benefits. While chitosan is often touted for its various uses, it’s important to remember that its role in addressing skin conditions like eczema is still being researched. For example, some studies suggest a potential link between hormonal changes from birth control and eczema symptoms, which is why it’s worth exploring resources like birth control and eczema symptoms to gain a comprehensive understanding of this connection.

Ultimately, chitosan’s role in overall health is still a subject of ongoing investigation.

Regulatory Aspects of Chitosan Use

Regulatory frameworks for chitosan vary across countries, often mirroring general food and material safety standards. Different countries have specific guidelines for food additives, cosmetic ingredients, and medical devices incorporating chitosan. For example, the FDA (Food and Drug Administration) in the United States has regulations concerning chitosan’s use in food products, ensuring safety standards are met. Similarly, the EU (European Union) has stringent regulations for chitosan use, reflecting a comprehensive approach to food safety and consumer protection.

Potential Health Benefits and Risks

Chitosan’s potential health benefits include its use as a dietary fiber supplement, aiding digestion and potentially promoting satiety. However, more research is needed to fully understand its long-term effects. Some studies suggest potential benefits in managing blood sugar and cholesterol levels. While generally considered safe, potential risks, like any dietary supplement, should be considered. Adverse effects are rare, but individual sensitivities can occur.

It’s crucial to consult with a healthcare professional before incorporating chitosan into a diet, particularly for individuals with pre-existing health conditions.

Regulations Governing Chitosan in Different Countries

Regulations for chitosan vary considerably across countries, often based on intended application. In the European Union, the use of chitosan in food is generally regulated through the European Food Safety Authority (EFSA) guidelines. The US Food and Drug Administration (FDA) regulates chitosan in food applications, often with specific guidelines for dietary supplements and food additives. Canada’s Health Canada regulates chitosan use in various applications, including food and pharmaceuticals.

Regulations vary based on specific applications and their intended use. For instance, chitosan used in medical devices might be governed by stricter regulations compared to food additives.

Summary Table: Chitosan Safety Data and Regulatory Guidelines

| Application | Safety Data | Regulatory Guidelines (Example Countries) |

|---|---|---|

| Food Additive | Generally safe for consumption in recommended dosages; potential for allergic reactions. | EU: EFSA guidelines; US: FDA regulations |

| Cosmetics | Biocompatible and often well-tolerated; potential for skin irritation. | EU: Specific cosmetic regulations; US: FDA guidelines |

| Medical Devices | Biocompatible and biodegradable; potential for specific side effects depending on application. | EU: Medical device regulations; US: FDA approval processes |

Future Trends and Research: Chitosan Everything You Need To Know

Chitosan, a naturally derived polysaccharide, is rapidly gaining traction in diverse fields. The ongoing research and development efforts are focused on pushing the boundaries of its applications and addressing global challenges through sustainable practices. This section explores the exciting future prospects of chitosan in various industries, highlighting potential advancements and the impact on sustainable development.

Latest Research and Development Efforts

Current research in chitosan science is exploring novel applications and enhancing existing ones. Scientists are investigating the synthesis of chitosan derivatives with tailored properties to improve its performance in specific applications. This includes modifying the molecular weight, degree of deacetylation, and surface chemistry of chitosan to optimize its interactions with other materials. Researchers are also developing advanced techniques for chitosan extraction and purification, aiming to increase efficiency and reduce production costs.

Emerging Trends in Chitosan Applications

The field of chitosan applications is experiencing significant growth, with emerging trends focusing on its biocompatibility and biodegradability. One trend involves integrating chitosan into bio-based composites and coatings for enhanced performance and sustainability. Another notable trend is utilizing chitosan as a drug delivery system, with researchers focusing on creating targeted drug delivery systems for improved therapeutic efficacy.

Future Prospects of Chitosan in Different Industries

Chitosan’s versatility makes it a promising material for a wide range of industries. In the biomedical field, chitosan-based scaffolds and wound dressings show promising potential for tissue regeneration and healing. The food industry is exploring chitosan as a natural food additive and preservative. The agricultural sector is investigating chitosan for pest control and plant growth enhancement.

Potential of Chitosan for Addressing Global Challenges

Chitosan offers potential solutions for global challenges. Its biodegradability and biocompatibility make it a sustainable alternative to synthetic polymers, addressing environmental concerns. Chitosan-based filtration systems are being developed for water purification, providing a cost-effective and environmentally friendly solution. In the context of agriculture, chitosan-based pest control strategies offer a more sustainable approach compared to traditional methods.

Potential of Chitosan in Sustainable Development

Chitosan’s inherent biodegradability and biocompatibility position it as a crucial component in sustainable development. By replacing petroleum-based materials with chitosan, industries can significantly reduce their environmental footprint. This trend aligns with the global movement towards environmentally friendly and sustainable solutions. Examples include using chitosan in packaging materials and agricultural applications.

Summary of Future Trends and Research Directions

| Future Trend | Research Direction | Potential Impact |

|---|---|---|

| Bio-based composites and coatings | Tailoring chitosan properties for specific applications | Enhanced performance and sustainability in various industries |

| Targeted drug delivery | Developing novel chitosan-based drug delivery systems | Improved therapeutic efficacy and reduced side effects |

| Water purification | Designing efficient chitosan-based filtration systems | Cost-effective and environmentally friendly water treatment |

| Agricultural applications | Exploring chitosan for pest control and plant growth enhancement | Sustainable pest management and improved crop yields |

| Biomedical applications | Creating chitosan-based scaffolds and wound dressings | Accelerated tissue regeneration and wound healing |

Ending Remarks

In conclusion, chitosan’s versatility and biocompatibility make it a promising material for a wide range of applications. From sustainable food packaging to innovative medical treatments, chitosan holds significant potential. As research continues and manufacturing processes improve, we can expect to see even more groundbreaking uses of this remarkable biopolymer in the years to come. This exploration into chitosan provides a comprehensive overview for anyone seeking to understand its importance and future role.